LED Cyr wheel notes: casting

Here’s some notes on casting…maying for myself when I go back to do this again and try to remember what I was doing.

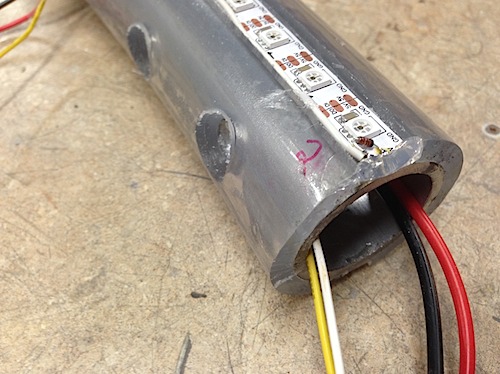

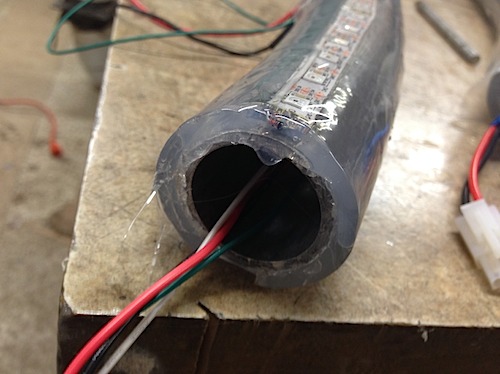

First, to get the curve, I would cut the LEDs every 6 and re-solder them together:

All us techie programmer know a curve is an approximation of straight lines; and mine are 6-pixel straight lines.

Next, casting: I had two materials to cast with (see Casting experiments). Smooth-on EpoxaCast 690, and some Polyester casting Resin. The resin is fairly cheap, and they sell it at my local Tap Plastics store (I discovered that after I ordered it on Amazon). I experimented with both, and they seemed about equal. However, the Resin was harder after it dried, while the smooth-on was sort of more plyable. I’m not sure if that is good or bad (yet).

My first official wheel piece didn’t go so well. I used the EpoxaCast, and tried taping over the groove horizontally (in line with the wheel curve), but this was a mess. I kept getting a lot of bubbles and it was just not going well.

In the above picture, you can see I bought a scale, as it is a two part epoxy measured by weight.

Eventually, I realized it was better to spread the tape perpendicular to the wheel…but even then, I got lots of air bubbles under it. Worse, the next day a bunch “drained” out, probably from capillary action:

Hmm..not so great.

So, I decided to try the Resin for the second casting. It went on really well, as I put the tape perpendicular to each piece and seemed good. But the next day, the resin (which dries MUCH faster than the Smooth-on Epoxy) was sort of “blotchy” under the tape. Grr. (Note: later I fixed this by putting some epoxy on top of it).

So, I tried the smooth-on epoxy again, and with the horizontal technique it was working pretty well, despite some spots getting air bubbles and dripping out.

One thing I would do is hot-glue fill in the edge to keep the epoxy running out:

After I taped it, I discovered I could “cotterize” it with more hot-glue to keep it from dripping:

The glue is fairly easy to cut off with an exacto knife.

Next thing I learned: tape makes a difference. I was using Heavy Duty Scotch shipping tape to “cast” the LEDs in; it pulls off pretty easily and cleanly. I ran out, and used the weaker/cheaper ACE tape.

Bad idea. It reacted funny with the epoxy:

Luckily most of the white opaque mess peeled off, but some I had to scrape off. Plus, this tape left a sticky residue. It was not the right tape to use.

Other notes: the temperature should be warm..ideally 70F or higher. The stuff takes forever to cure when thin; it says 24 hours, but it seems much longer — at least 36, but probably 48 hours. And I think it takes a week before it is fully cured. Outside temps have been 50-60F (or up to 70F during the day).

Do you know where can I buy LED cyr wheel?