Milling machine tune up

My 1990 Enco Milling machine was starting to get quite a bit of shake at certain speeds. It has a variable speed head, and one of my friends, Bevan, recommended against getting the vari-speed, since they are sometimes prone to having trouble. But, I really do love being able to dial in the speed with the turn of a small wheel, and even though it was a pain to do, I tuned up the head and now it runs smooth again.

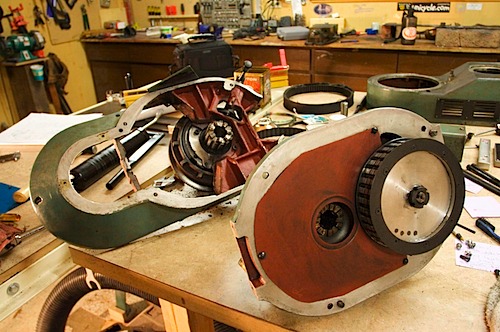

I took the head apart, carefully labeling stuff on my bench:

The main problem was a bad v-belt. The old one somehow managed to twist backwards, and was getting all chewed up and tossed a bunch of dust into the head cover:

Yikers, look at that mess of a belt:

Some more details of what a milling machine head looks like:

I also had to take the quill and quill housing off to fix a broken bolt that rotates the head left/right (we broke it when we moved the thing into my shop). It wasn’t too hard to replace, but it was a pain getting the quill back on (the thing is heavy!). Ultimately, I set the quill on a board and raised the knee up to get it into place, while Louise pushed the bolts in (no pictures of the process, sorry!). Getting the motor back on top of the head was a pain! The motor is very heavy, and I couldn’t get the variable speed disc off the motor, so I had to work the variable speed belt around it, which took some muscling and luck.

I also cleaned up some loose wires I noticed, and once the thing was back together it started purring like a happy kitten.